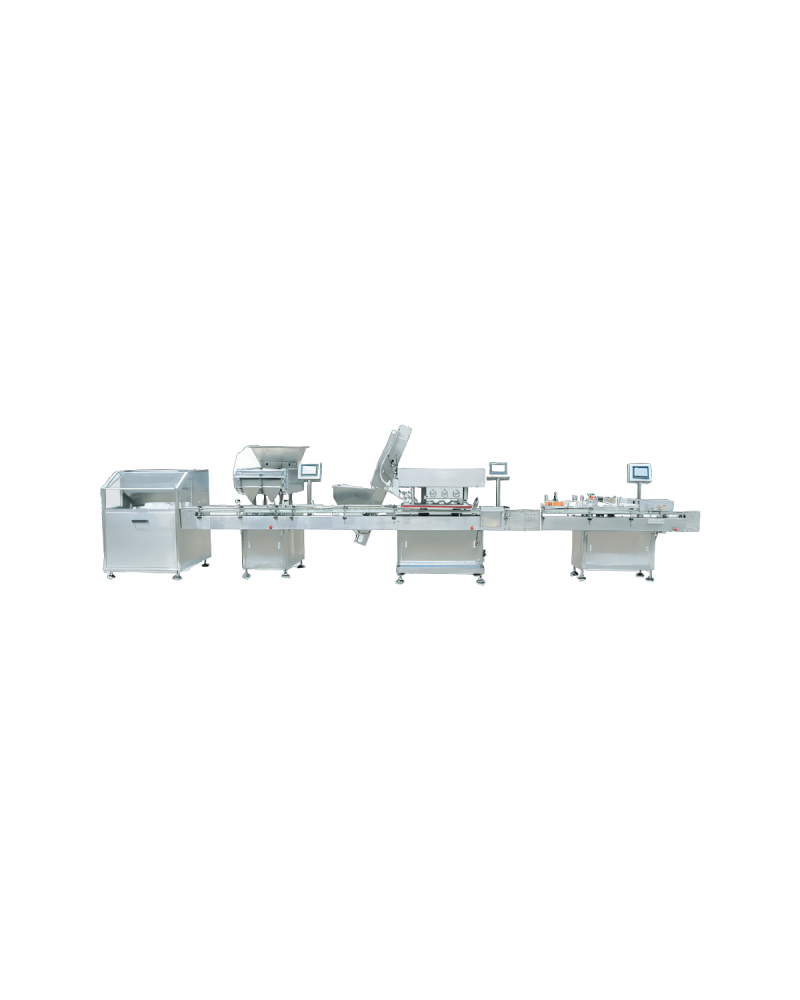

Filling and counting machine mod. GS-8

The block bottle device on the through track of the transport system ensures that the bottles coming from the rotary table remain in the bottling position, waiting to be filled.

The product enters the container thanks to the vibration of the corrugated feeding plate, there is a photoelectric counting sensor.

Main features:

- Strong compatibility, can count and bottle various types of preparations solids or granules for example: tablets, capsules, soft capsules (transparent and non-transparent), pills, etc.

- Vibration discharge material: 8 dedicated vibration tracks for 8 entries, with special filling system partial with patented flap, the discharge of the medicine is homogeneous and stable without damage.

- Anti-dust: the machine can work stably even in conditions of excessive dust thanks to photoelectric detection.

- Correct counting: with the automatic counting of the photoelectric sensor, the bottling error is lower than what is required by current regulations.

- Functionality: it has various alarm and control functions, for example no bottle passes without being counted, automatic fault checking, etc.

- Auxiliary function: The counting photoelectric sensor detects that there is no bottle and stops automatically.

- Simple operation: All data can be set according to your needs. It can store up to 10 recipes.

- Maintenance: easy to disassemble, clean and change components without tools.

- Dust collector (optional): a container for collecting dust is available which reduces dusting on the entire line.

Specifications:

| Attribute | Value |

|---|---|

| Applicable bottle shape | round, square plastic bottle, etc. |

| Filling material | capsule sizes from 00 ~ 5 #, soft capsules, tablet diameter from Φ 3~20 mm, tablets at special shape, sugar-coated tablet, pill diameter from Φ3~20 mm. |

| Production capacity | 10-30 bottles per minute (depends on bottle size, by the filling quantity and the size of the tablet) |

| Range for setting the number of pieces to count | 1-9999 | < /tr>

| Power supply | AC220V 50Hz 0.6kw |

| Accuracy rate | >99.5 % |

| Air pressure | 0.6Mpa |

| Overall dimension | 660 × 1280 × 780 mm |

| Weight | 280 Kg |

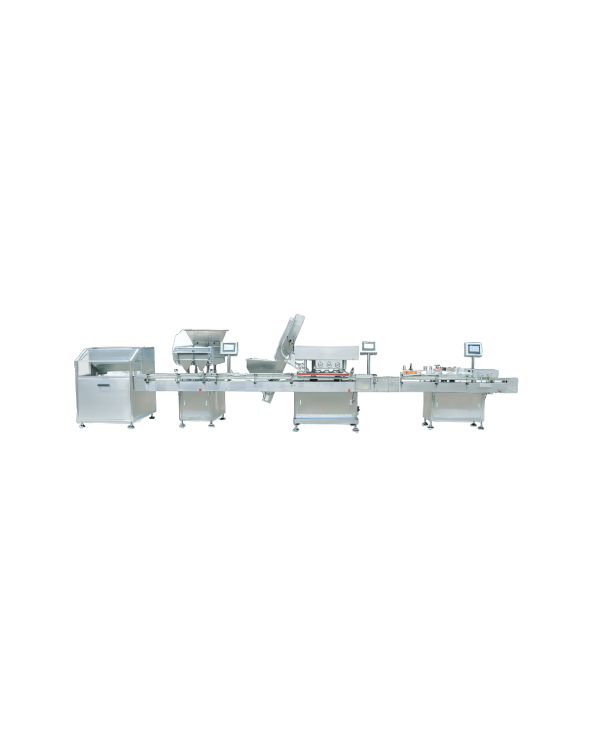

High speed capping machine mod. D90

The D901 in-line capping machine handles a wide range of containers and offers quick and easy format changeover that maximizes production flexibility.

Main features:

< ul>Specifications:

| Attribute | Value |

|---|---|

| Bottle dimensions | Φ30 ~120 mm, height (customizable based on the format) |

| Dimensions | 1800 mm × 850 mm × 1850 mm (length × width × height) |

| Weight | 600 kg |

| Electrical requirements | Power: 1.8 kW, Voltage: 220 V, Frequency: 50-60 Hz |

| Air pressure | 0.6 MPa |

LTB-A labeller

< p>The labeling machine applies an adhesive label on the bottles: the label is taken off from the labeling roller and pasted on the body of the bottle.It is a modern machine integrating mechanism and electricity with good and reliable working properties.

The advantages of adhesive labels are: mold resistance, long life, and cleanliness.

It is widely used in the fields of medicine, food, stationery, cosmetics,

Automatic Line for...

€0.00